[2009-04-29] DIY glassblowing swivel

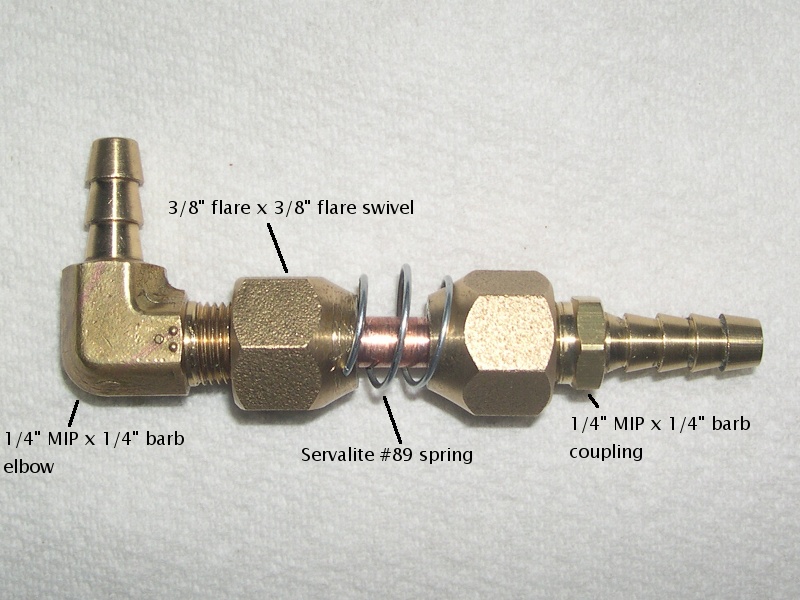

This is the latest result of my ongoing quest to assemble a set of tools for scientific glassblowing on the cheap. This is a brass right-angle swivel; it hooks into the blow hose between the mouth-piece and the work-piece so that it is possible to smoothly rotate the work without twisting up the blow hose. Professional glassblowing supply houses will sell you a custom-manufactured brass fitting for this purpose. They cost about $20 before shipping. I put this guy together for $7 from stuff at the corner hardware store. The required parts are shown in the photograph. From left to right, they are:

- 1/4" hose barb x 1/4" MIP elbow

- 3/8" flare x 3/8" flare swivel

- Servalite #89 spring

- 1/4" hose barb x 1/4" MIP straight coupling

The most interesting feature of this assembly is that it includes mismatched male and female threads. I discovered that 1/4" male iron pipe (MIP) fittings thread nicely into 3/8" female flare fittings, at least in brass, and at least over short distances, in spite of the fact that they are not nominally compatible. This convenient anomaly allows a compact and inexpensive right-angle swivel assembly from only three common brass fittings. The assembly does leak, very slightly, but (surprisingly) the leak is not from the mismatched threaded joints--it's from the center of the flare swivel. With the internal flares of the swivel not fully seated against the appropriate male fittings (3/8" male flare), they're free to woggle around a bit and thus the seal is less than perfect. In practical use, this makes no difference whatsoever in the swivel's performance, as the leak rate is relatively slow.

However, for the sake of completeness, I decided to add a spring to maintain a light pressure between the two ends of the flare fitting, which reduces its leakiness by keeping the ferrules properly seated against the flares most of the time. I fit the Servalite #89 spring around the intact swivel by prying it open slightly and carefully threading it around the copper tubing in the middle of the swivel, then compressing it back to shape once it was in place. I found that using the complete spring result in a swivel action that was a trifle too stiff, so I trimmed off one full turn of the spring from each end using wire-cutting pliars. Now it turns freely and still has plenty of compression to keep the flares seated.

last modified 2009-04-29